Updated 4/2023

August, 2023

Please note: The longstanding AXIS/Iron series has been phased out of production and is being replaced by the all new AXIS/RR (round-race) series race rotors. Please click here for more info on this.

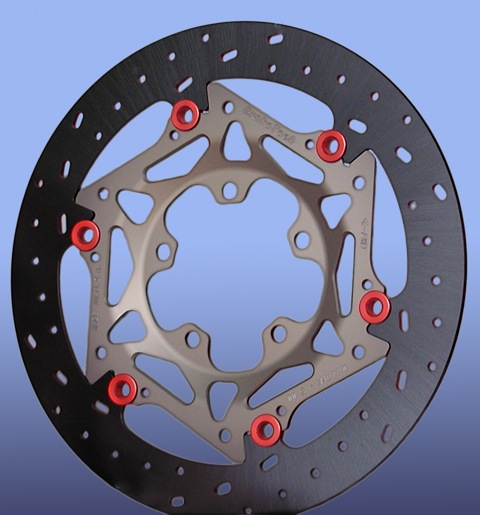

The exclusive BrakeTech AXIS™ series Ductile Iron full-floaters provides a higher coefficient of friction over traditional stainless steel rotors, with more feel and feedback at the brake lever. The patented AXIS Design floating system is many times stronger than conventional semi-floating brake rotors. The heart of this leading edge system has the floater buttons controlling radial and axial float only, they are non load-bearing. All of the considerable braking forces are channeled through the trademarked Direct-Link™ architecture, comprising over an 800% increase in surface area load transfer as compared to conventional floating brake rotors…simply far superior by design!

Although iron provides a higher coefficient of friction over conventional stainless brake rotors, that is not the case with our proprietary stainless steel. Iron is well known for more feel and feedback at the brake lever. But get them wet – they’re going to rust. If you’re a fair weather rider, then it’s a non-event and not an issue. However, if you ride distances where inclement weather is a definite possibility, you’re better off with our late generation AXIS/Cobra stainless steel series in the optimized petal design.

PRODUCT FEATURES:

- Patented AXIS Design – featuring Direct-Link™ load transfer system

- U.S. Patent No. 6,957,726

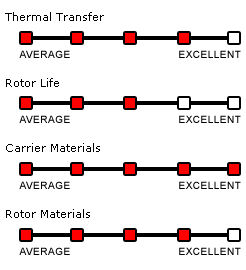

- 50% greater Tensile Strength and Fatigue Strength: Ductile Iron vs Gray Iron

- CNC machined from billet (continuous cast bar) – not porosity prone gravity cast molds

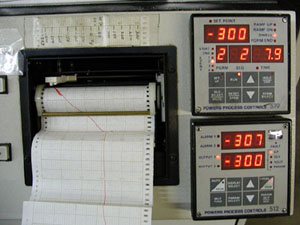

- CRYOGENIC treatment for improved wear resistance

- Greater thermal transfer capability than stainless steel

- Reduced wear from shear forces – longer rotor life

- Carriers CNC machined from premium grade billet aluminum bar – not stamped plate

- Hard-anodized to military grade specifications

- Made in the U.S.A.

BMW S1000RR SERIES

On the new front is the AXIS/Iron Performance Upgrade series rotors for the BMW S1000RR. A significant departure from our current offerings as this all new design employs a 5-pt mounting system attaching to the spokes of the OE wheel. The new BTB-10 (320mm x 5mm) features some very innovative and exclusive design elements that truly set it apart from anything else on the market.

The BTB-10 series is a dedicated new design architecture expressly for the spoke mounted S1000RR. In order to obtain the strength and stability we require, design development incorporates what we call an InterPhase Link system to increase thrust-face area for improved assembly strength and thermal transfer. Effectively then, this novel mechanism achieves a 10-pt thrust-face configuration with five bobbins, seamlessly matching the symmetry of the OE wheels. Manufactured in our Billet Iron and the Cobra stainless.

Manufactured at our standard spec of 5mm for use with the OE Brembo 4-pad caliper, positions this new offering in our Performance Upgrade Series. The new design provides a significantly higher overall level of capability compared to the standard issue OE system. However, this is not a race-spec floater. For those individuals or race teams campaigning the S1000RR, should utilize our HP4 race-spec series option whenever possible (BTR-B1 in the Cobra SS or new AXIS-RR stainless steel race rotors).

PERFORMANCE UPGRADE SERIES

• BTB-10.L & R: AXIS/Iron 320mm x 5mm, spoke mount

• BTB-10.SL & SR: AXIS/Cobra 320mm x 5mm, spoke mount

Click here for the BMW price and application guide

Sintered Metal Brake Pads on Iron?

There does indeed exist a universal prohibition against the use of sintered metal pads on generic cast iron rotors, we have the same warning. But this caveat is more specifically targeted to old-school gray cast iron and particularly of the individual molding, gravity feed casting type. That combination was and is inherently problematic with a propensity towards suffering from thermal stress induced fracturing. Not good.

The AXIS/Iron on the other hand is a significantly different animal. Firstly, it is CNC machined from American made high grade nodular ductile iron, not gray iron. Secondly, it’s a genuine billet part, sawed from continuous cast bar (which eliminates porosity and the problems associated with that). Thirdly, it is an inherently stronger material with tensile strength more akin to steel than gray iron. Plus, besides traditional heat-treat, we also Cryogenically process them to improve their abrasion resistance and reduce wear. But bear in mind, they are still “softer” than stainless steel, which simply stated means you cannot run any pad you want without the potential for problems developing…

We test extensively with virtually all the Ferodo sintered metal pads to assure compatibility with our ductile iron rotors, which is why we can recommend the Ferodo SinterGrip ST, XRAC and ZRAC pads for this application. Though along with virtually all other sintered metal formulations, they will likely result in a somewhat shortened rotor life compared to the organic alternative. For those with a nagging concern regarding the wear issue, we recommend the new Carbon/ceramic CPro race pads. They are a brilliant performer on stainless, and even better on iron and as such, are more than worthy of your consideration for race use on all iron rotors.

AXIS/Iron Black GunKote: This is a rust inhibiting coating which is thermally bonded on to minimize corrosion. It must be cleared from the pad sweep area before the rotors become fully functional. Please click here for the one page instruction guide: AXIS/Iron Rotor Clearing instructions

At BrakeTech, we strive to bring you the best in braking…

Race-Spec

-

DUCATI 1098 / 1198 & STREET-FIGHTER

-

DUCATI 1199/1299 & V-4 PANIGALE

The AXIS/Iron competition series 330mm x 6mm semi narrow-band race rotor for the stunning 1098/1198/1199 models and now the Panigale V-4. These competition designed full-floaters are all business, expressly developed for optimal performance with the Brembo M4/M50 monobloc calipers whether on the track or carving up a canyon. Optional features for the 1098/1198 include the requisite TC triggers to perform seamlessly with your DTC electronics. The race-spec 6mm thick narrow-track configuration increases thermal capacity for top level Superstock racing, while our patented floating system minimizes brake-drag and maximizes performance. So regardless whether you’re a top level racer or a weekend warrior…we have you covered!

BTD-36 series, covers the 1098 thru the Panigale V-4 with superb braking power and panache without peer

AXIS/Iron 330mm x 6mm race-spec with DTC triggers

- See the AXIS/Rear Floater Section for the Matching Hi Performance Rear Race-Rotors

AXIS/Iron 330mm x 6mm & Over-Size Race Kits

Regarding the size difference (310mm vs 330mm), it all comes down to the mechanical advantage produced by moving the fulcrum point 10mm further out for more leverage on the wheel. There is also the proportional advantage of greater thermal capacity created by more mass and surface area of the larger unit. Another inherent improvement in all the AXIS series floaters is that they are indeed genuine full-floaters, free to move on their carriers. This reduces brake drag along with all the endemic benefits associated with that including brakes which run cooler than their semi-floating counterparts.

Available for:

Aprilia

- RSV-4, all models (`09-16 as oversize kits)

Ducati

- 1098 thru V-4 Panigale

- Monster 1200

- MultiStrada `015+

- Street Fighter 1098 & V-4

- 1299 Super Leggera

Honda

- CBR1000RR-R / SP, 2020+

Kawasaki

- ZX10R/RR, all models (`08-15 as oversize kits)

- H2R, `015+

- ZX14R, (`06+ as oversize kits)

Suzuki

- GSX-R1000, (`05+ as oversize kits)

- Hayabusa, (`08+ as oversize kits)

- B-King, (`08+ as oversize kits)

Yamaha

- YZF-R1, (`07+ as oversize kits)

- VMX-17, (`09+ as oversize kits)

A perfect match to these competition designed full-floaters is the new Ferodo Carbon/ceramic CPro race pads. Inspired by the car race division, all of which in that arena are formulated for iron rotors, yet perform brilliantly on stainless as well. But truly, the CP’s produce their best result on iron and effectively magnify the performance parameters you’d experience with them on stainless rotors.

From our point of view, if you can deal with the mechanical issues relative to the larger diameter rotors (getting the calipers on and off quickly, etc.), you’ll end up with more powerful brakes as described above. No doubt that’s why Ducati opted for the 330’s starting with the ground breaking 1098 on through to their latest Superbike, the Panigale V-4.

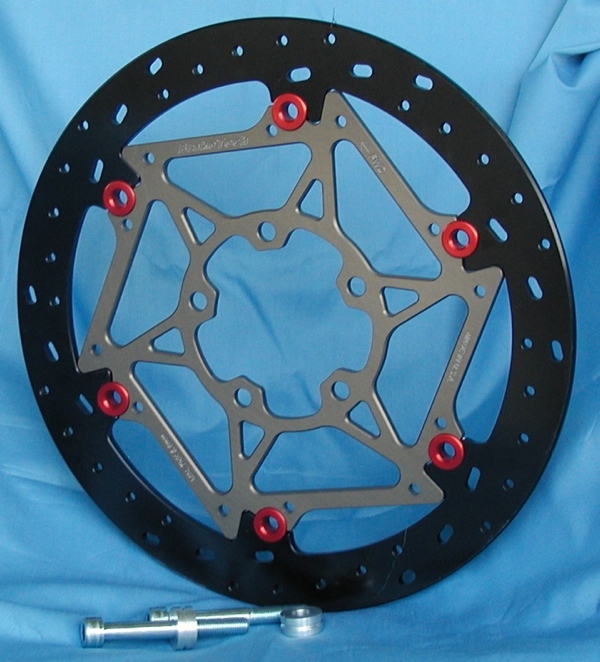

New 330mm Over-Size Race Kits includes the `05+ GSX-R1000’s shown with the optional blue bobbins:

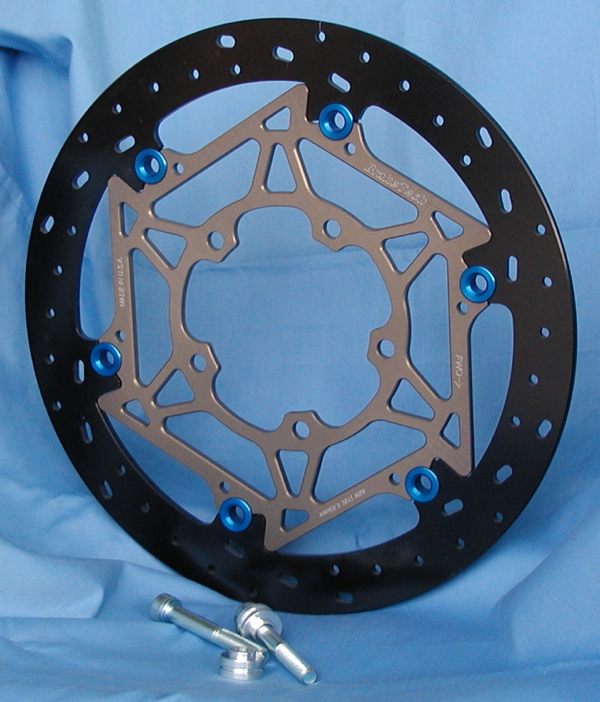

Another new addition to the expanding 330mm ultra upgrade kits are the AXIS floaters for the `08+ Hayabusa and B-King, kits come complete with longer grade 8 bolts and special dowel pin positioning caliper spacers:

AXIS/Iron 330mm Race-Spec Rotors

The AXIS/Iron race-spec 330mm x 6mm semi narrow-band floaters are available for both European and Japanese models. Although designed for the most demanding race conditions, they also perform brilliantly in the canyons as well. But get them wet and they’ll rust.

NOTE: Not legal in AMA or FIM competition (see the Cobra SS, AXIS-RR or AXIS/SBK race rotors instead).

The AXIS/Iron race configuration was designed expressly for those preferring the incomparable feel and feedback at the lever. The core focus was to develop a purpose built 330mm x 6mm semi narrow-band architecture specifically optimized for use with late generation OE calipers. The thicker 6mm design strategically increases mass at the critical interface, substantially improving their ability to deal more effectively with the high thermal loads encountered in top level racing. Another benefit is greater consistency in braking performance throughout a race from start to finish.

Click on the following for application reference numbers & pricing

• Aprilia

• Ducati

• Honda

• Kawasaki

• Kramer

• KTM

• Suzuki

• Yamaha

Although designed specifically for use with OE calipers, this new range of race rotors will perform flawlessly with the Billet GP type race calipers as well.

BTR-A2 / Aprilia RSV-4 Race, all 330mm x 6mm

BTR-H8 / CBR1000RR-R • SP race-spec, late model 330mm x 6mm

• BTY-35 series: 330mm x 6mm race-spec YZF-R1/M