Nicky Hayden (circa 2015, RIP) on Fred Wilhelmi’s immaculately prepared CRF450R S/M race bike

SuperMoto: Ride like you mean it…with Power at your fingertips

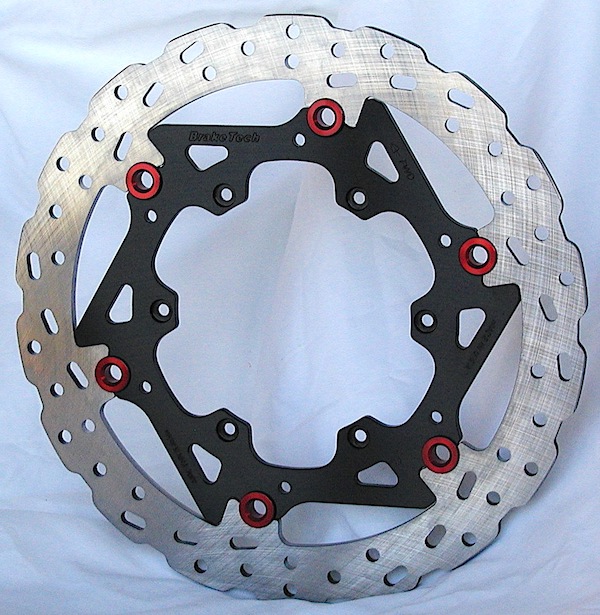

The patented AXIS™ series Racing brakes and kits are all about demanding tight track SuperMoto racing where power and control is paramount. Feel and feedback at the lever can make all the difference on fast corner entries which is a core focus of our race rotors. Not just another brake rotor, the patented AXIS full-floaters feature our uniquely hi-tech architecture that provides complete control of both axial and radial float. This pivotal development increases load capacity under severe braking conditions in the rarefied atmosphere of top level racing…an exclusive trademark of the AXIS series race rotors.

Carriers are CNC machined from high tensile strength U.S. spec extruded billet aluminum. Available in Black Diamond or titanium bronze hard anodize finishes. Three floater button finishes are available: Standard red, optional blue or black.

AXIS/RR Pre-production 320mm x 6mm race-spec rotor for FS450 (BTR-KT6R)

AXIS 310mm & 320mm OVER-SIZE Race Kits:

With focus squarely centered on racing, the advanced design AXIS™ full-floaters offer substantially improved performance in terms of both modulation at the lever and overall braking power. The patented advanced floating system of the AXIS series full-floaters is many times stronger than conventional semi-floating brake rotors. The heart of this patented design has the floater buttons controlling radial and axial float only, they are non-load bearing. All of the considerable braking forces are channeled through the trademarked Direct-Link™ architecture comprising over an 800% increase in surface area load transfer as compared to conventional floating brake rotors…simply a superior design!

We offer them in in our new AXIS/RR as well as the brilliant performing Cobra SS (both in our proprietary stainless steel). The Cobra features our optimized petal design with none of the downside problems associated with the wave type rotors.

Plus we are the first major brake rotor manufacturer to include hi-tech Cryogenic processing on the entire line of performance rotors as a standard operational component of manufacture. The inclusion of this advanced technologically employing computer controlled, the 24 hour deep cycle freezing treatment provides improved wear resistance and longevity.

On brake pads for for heavy track use, the new Ferodo carbon/ceramci CPro is a true standout. They feature a progressive rising torque curve for terrific feel and feedback at the lever, plus a higher thermal threshold than most sintered metal pads.

Click here for the application / fitment guide